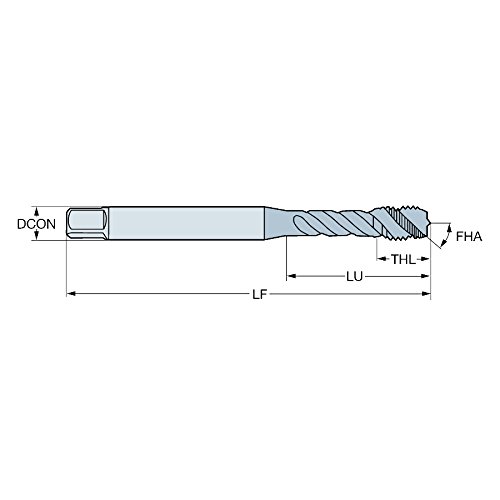

Part of the CoroTap 300 product family. Spiral flute taps are the best option for blind holes. The flute transports the chips out of the hole and is also used for cutting fluid. There are different helix angles suitable for different applications. PRODUCT SPECIFICATION: Grade: C110 ; ISO Cutting Tool Material: HSS-PM ; Coating Process Type: PVD ; Coating Type: AlCrN ; Substrate Type: HSS-PM ; ADINTMS, Adaptive Interface Machine Direction: Tap shank ANSI -inch: 0.141 x 0.110 ; BHFP, Blind Hole Function Property: 1 ; BSG, Basic Standard Group: DIN 2184-1/ANSI ; CNSC, Coolant Entry Style Code: 0: without coolant ; DCON, Connection Diameter: 3.5814 mm ; DCON, Connection Diameter: 0.140984 inch ; DN, Neck Diameter: 2.5 mm ; DN, Neck Diameter: 0.098425 inch ; FHA, Flute Helix Angle: 45 deg ; LF, Functional Length: 56 mm ; LF, Functional Length: 2.20472 inch ; LU, Usable Length: 20.5 mm ; LU, Usable Length: 0.807087 inch ; NOF, Flute Count: 3 ; NORGMX, Maximum Regrinds: 0 ; PHD, Premachined Hole Diameter: 2.85 mm ; PHD, Premachined Hole Diameter: 0.112205 inch ; TCTR, Thread Tolerance Class: 3BX ; TD, Thread Diameter: 3.5052 mm ; TD, Thread Diameter: 0.137992 inch ; TDZ, Thread Diameter Size: UNC #6-32 ; THBTP, Thread Back Taper Property: 0 ; THCHT, Threading Chamfer Type: C ; THL, Threading Length: 7.2 mm ; THL, Threading Length: 0.283465 inch ; TPI, Threads Per Inch: 32 ; WT, Weight Of Item: 0.006 kg ; WT, Weight Of Item: 0.0132 lbs ;

Sandvik Coromant T300-XM100AE-6-32C110 CoroTap 300 cutting tap with spiral flutes

NZD $40.99

- Benefits of this product family: Chamfer C (2-3 threads) and Chamfer E (1.5 – 2 threads)

- Edge treatment for reduced axial force and torque, makes the tool run more smoothly

- The design of the spiral flute secures a constant rake angle and gives a constant cutting process

- Back chamfer, used on taps with high helix angle, reduces torque and chipping

- Taps with high spiral angle give excellent chip evacuation to thread up to 3 × dia in blind holes

In stock